Electromagnetic Field Cuts Steel

Electromagnetic Fields As Cutting Tools

by Science Daily

December 10, 2009

The bodywork on motor vehicles must be sufficiently stable, but processing the high-strength steels involved -- for example punching holes in them -- can prove something of a challenge. A new steel-cutting process will save time, energy and money in the future.

Squealing tires and the crunch of impact -- when an accident occurs, the steel sheets that form a motor vehicle's bodywork must provide adequate impact protection and shield its passengers to the greatest extent possible. But the strength of the steels that are used throw up their own challenges, for example when automobile manufacturers have to punch holes in them for cable routing. Struggling to pierce the hard steel, mechanical cutting tools rapidly wear out. And because they also leave some unwanted material on the underside of the steel (burr, as the experts call it), additional time has to be spent on a finishing process. One possible alternative is to use lasers as cutters, but they require a great deal of energy, which makes the entire process time-consuming and costly.

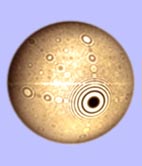

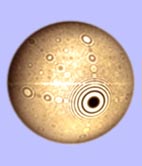

Working together with a number of partners including Volkswagen, researchers at the Fraunhofer Institute for Machine Tools and Forming Technology IWU in Chemnitz have come up with another way to make holes in press-hardened steel bodywork. Dr. Verena Kräusel, head of department at the IWU, explains: "The new method is based on electromagnetic pulse technology (EMPT), which was previously used primarily to expand or neck aluminum tubes. We've modified it to cut even hard steels. Whereas a laser takes around 1.4 seconds to cut a hole, EMPT can do the job in approximately 200 milliseconds -- our method is up to seven times faster."

Another advantage is that it produces no burr, thus doing away with the need for a finishing process. Stamping presses become superfluous, and no costs arise from the need to replace worn-out parts.

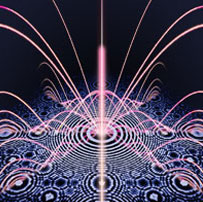

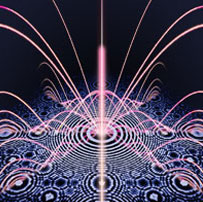

The pulse generators comprise a coil, a capacitor battery, a charging device and high-current switches. When the switch closes, the capacitors discharge via the coil within a matter of microseconds, producing a high pulsed current. The coil converts the energy stored in the capacitors into magnetic energy. To be able to use this process to cut steel, the researchers simply had to modify the coil to ensure the resulting electromagnetic field is strong enough: the pressure with which the field hits the steel must be so high that it forcibly expels the material from the sheet.

"The impact pressure on the steel is approximately 3,500 bar, which equates to the weight of three small cars on a single fingernail," says Kräusel. PSTproducts GmbH in Alzenau provided the original EMPT system. With regard to the customer demands the researchers develop now the coils for various cutting geometries.

Analysis

This automobile industry research has apparently replicated one of the ancient eletromagnetic field techniques used to cut the giant stones witnessed in neolithic architecture around the world. Yet the synthetic limestones that comprise most of the mass of the Great Pyramid were not cut, but poured like concrete as revealed by their low-density and exotic consitutuents. The red granite stones which the line the Great Pyramid's interior chambers, however, are comprised of rose quartz that was likely cut to its precision dimensions using the exact same electromagnetic techniques recently reestablished by the Fraunhofer Institute.

The application of these ideas to the creation of new psychoacoustic temples all over the world will take time, but the use of this technology in the infrastructure of Big Oil will not be able to proceed much longer, as the planetary changes cause major problems for the auto industry, including the potentially deadly spontaneous acceleration and piezoelectric fires - not to mention the extremely lethal oil spill now threatening the world's oceans and land-based life. It will take a powerful series of events to refocus the errant human consciousness into proper awareness and action, and this is exactly what the planet has in store for humanity, as we approach the cosmic illumination of the Red Dawn on December 22, 2012.